Project Overview

We collaborated with a medium-sized logistics center in Saudi Arabia to provide a customized outdoor single girder gantry crane. The crane has a lifting capacity of 16 tons and is equipped with a CD-type electric hoist. It is primarily used for loading and unloading goods, sorting, and temporary storage management in the outdoor yard. The project, from design to installation, took approximately three months and was delivered and put into operation in early November 2024.

Customer Requirements

The equipment must withstand Saudi Arabia’s high-temperature, dusty outdoor environment, with good rust and dust resistance.The crane’s span must cover the main working areas of the yard to meet flexible handling needs across different cargo locations.The operation must be simple and flexible, supporting wireless remote control to enhance outdoor work safety.The overall solution must be cost-effective, aligning with the budget and operational conditions of small to medium-sized enterprises.

Solution

We provided the customer with the following configuration:

Equipment Selection

- Main structure: MH-type single girder gantry crane with a box girder design, balancing lightweight construction and load-bearing capacity.

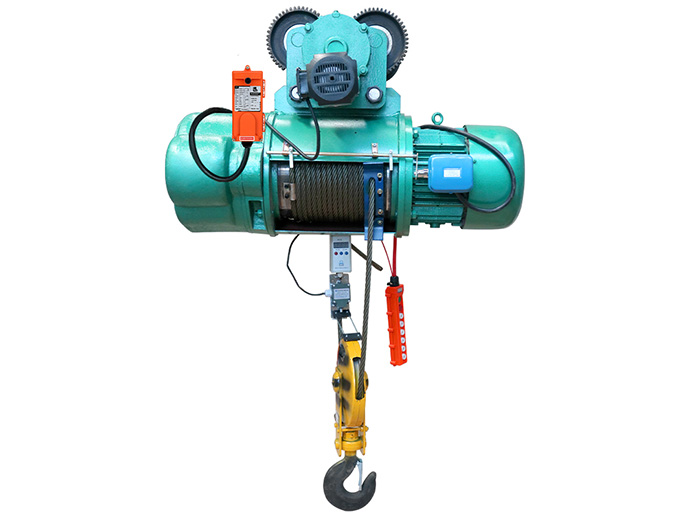

- Configuration: 16-ton CD-type wire rope electric hoist with IP55 protection rating, suitable for dusty outdoor environments.

- Surface coating: Epoxy zinc-rich primer + polyurethane topcoat process to enhance weather and corrosion resistance.

Adaptive Design

Customized span of 15 meters and lifting height of 10 meters to match the yard layout.

End beams equipped with double-flange wheels and angular bearing boxes to improve stability on outdoor tracks.

Operation and Maintenance Optimization

Standard wireless remote control system allows operators to control the crane safely from flexible positions.

Electrical system integrates basic safety features such as overheating protection and overload limiters.

Modular assembly design facilitates future maintenance and component replacement.

Customer Feedback

“This crane is very flexible to operate. The wireless remote control makes it much easier and safer for workers to move goods around the yard. The structure is lighter than we expected but remains stable during use, which suits our site where layout adjustments are frequent. Although it hasn’t been in use for long, it has performed well so far and meets our daily operational needs.”

Project Results

Improved Operational Efficiency: Loading and unloading times were reduced by approximately 25% compared to previous equipment, significantly improving yard turnover efficiency.

Strong Environmental Adaptability: The crane has operated for six months without any downtime due to high temperatures or dust.

Cost-Effectiveness: The solution was completed within the customer’s budget, with straightforward and affordable maintenance.

Enhanced Operational Safety: Remote control operation reduced the need for personnel to climb ladders, lowering the risks associated with outdoor aerial work.

Future Flexibility: The lightweight structure allows for easy relocation if the yard layout needs adjustment in the future

This case demonstrates our ability to provide practical and adaptable lifting solutions for customers of varying scales. We focus on the reliability and operational convenience of the equipment in real-world scenarios, ensuring that every crane we deliver integrates seamlessly into our customers’ workflows and creates lasting value.