Project Overview

We successfully exported six units of 15-ton HD series European-style single girder bridge cranes to a leading automotive parts manufacturer in Poland. The project aimed to provide an efficient and reliable material handling solution for their newly built, highly automated production line. All equipment has been smoothly installed, commissioned, and passed final acceptance. They are currently operating excellently, strongly supporting the client’s core objectives of enhancing production logistics efficiency and workshop space utilization.

Client Requirements

During the expansion of their modern factory, the Polish client faced specific challenges and needs:

1.Space Optimization: Narrow column spacing in the workshop made traditional cranes too large. They needed cranes with a compact structure and low headroom to maximize the use of existing factory space.

2.Efficient and Precise Handling: Fast production cycles demanded smooth crane operation and precise positioning for the high-frequency, rapid transfer of molds and large workpieces.

3.Low Operational Costs: Seeking equipment with low energy consumption and easy maintenance to reduce long-term operational expenses.

4.Compliance with European Standards: All equipment must strictly comply with local safety and quality standards such as EU CE certification and Machinery Directive.

5.Reliable Turnkey Service: Required the supplier to provide a full-range service from design and manufacturing to export customs clearance and remote technical installation guidance.

Our Solution

Addressing the client’s specific needs, we provided customized HD series European-style single girder bridge cranes and integrated services:

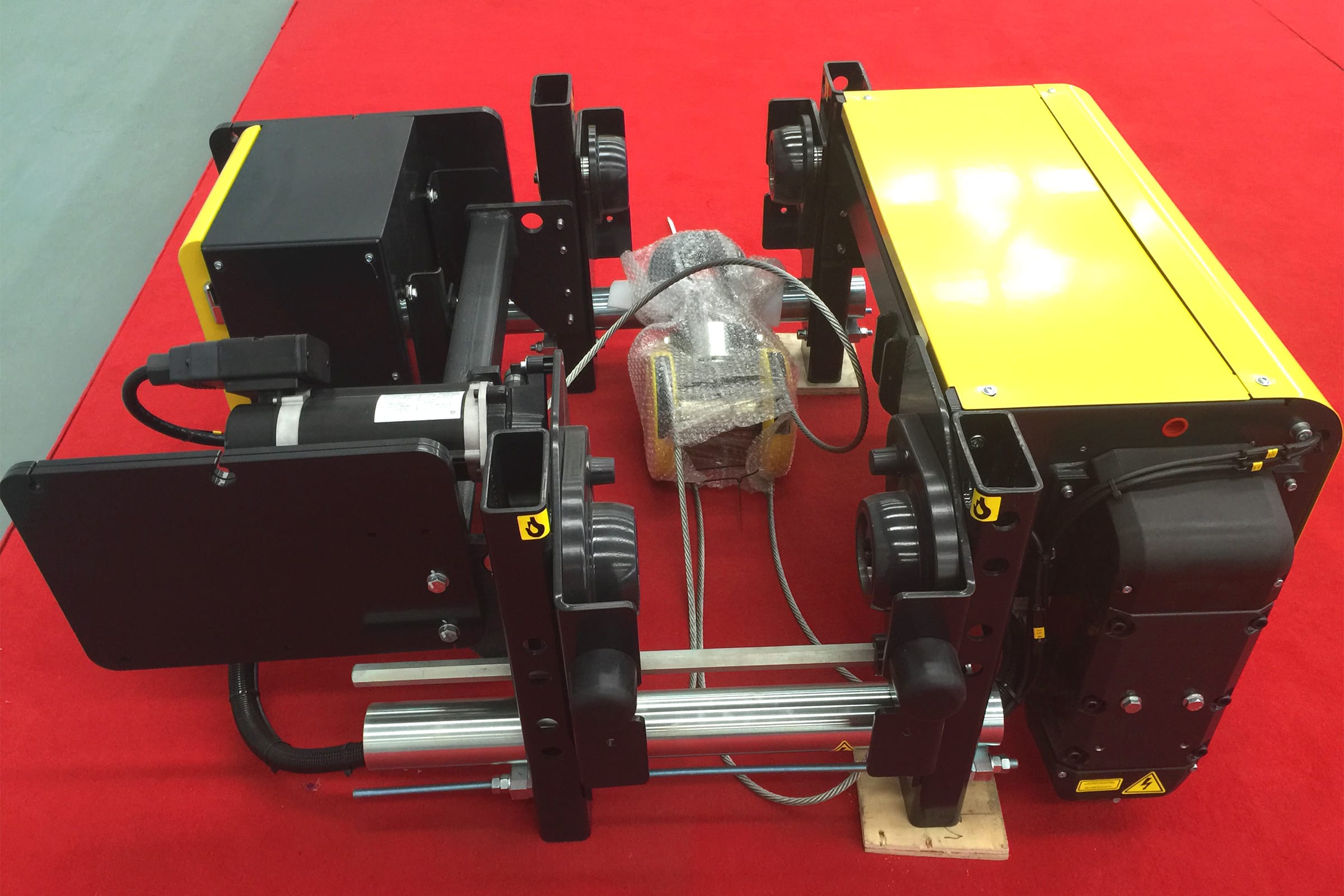

1.Customized European Design: Provided compact end carriages and an optimized main girder design, achieving a smaller wheelbase and very low headroom. This perfectly adapted to the client’s limited workshop layout, improving space utilization.

2.High-end Core Component Configuration: The cranes utilize internationally renowned brand frequency conversion drive systems, ensuring smooth operation and precise positioning. Paired with high-strength wire rope electric hoists, they offer stable lifting and high durability.

3.Energy Saving & Intelligent Control: Equipped with an energy feedback system and LED lighting, significantly reducing energy consumption. Wireless remote control operation was provided as an option, enhancing operational flexibility and safety.

4.Full-process Compliance & Support: Ensured all design and manufacturing fully complied with European regulations like CE/PED, providing complete certification documents. Our team handled all export procedures and provided detailed installation drawings, remote video debugging guidance, and operation/maintenance training.

5.Efficient Project Execution: The timeline from contract signing to delivery was only 14 weeks, demonstrating efficient supply chain management and project coordination.

Client Feedback

“We are extremely satisfied with the cooperation with our Chinese supplier. These six European-style cranes not only fully met our stringent requirements for space and efficiency but their exceptional operational smoothness and low failure rate even exceeded our expectations. The supplier’s professional team was highly responsive in technical communication and remote support, ensuring the project’s smooth implementation. This was a very successful procurement experience.” — Mr. Piotr Nowak, Client Project Director

Project Achievements

Successful Delivery & Operation: All six 15t HD European-style cranes were successfully installed and put into daily high-intensity operation at the client’s Polish factory.

Significant Efficiency Improvement: Material handling efficiency increased by approximately 30%, and precise positioning reduced workpiece adjustment time.

High Space Utilization: The optimized design freed up more workshop floor and overhead space, providing flexibility for future layouts.

Reduced Operational Costs: The energy-saving design and low maintenance requirements have brought significant long-term cost savings for the client.

Foundation for Long-term Cooperation: The successful implementation of this project earned the client’s high trust and laid a solid foundation for deeper future collaboration.