Gantry cranes are essential equipment at port terminals, widely favored for their outstanding stability and high efficiency. Selecting the right crane is a systematic decision that requires comprehensive consideration of multiple factors to ensure it perfectly aligns with port operations, enhancing overall handling efficiency and safety.

1. Matching Actual Port Conditions: Dimensions and Load Capacity

The primary basis for selection is the port’s own physical conditions and operational requirements. It is necessary to accurately evaluate the terminal layout, available space, and track length to ensure the crane’s span, height, and operating range can be seamlessly integrated, allowing free and unobstructed movement within the terminal area. Simultaneously, the crane’s rated lifting capacity and load spectrum must be scientifically determined based on the maximum weight, typical specifications of daily handled cargo, and peak operational periods. It is advisable to include a reasonable safety margin to accommodate future business growth or special cargo handling needs.

2. Emphasizing Operational Performance and Safety Assurance

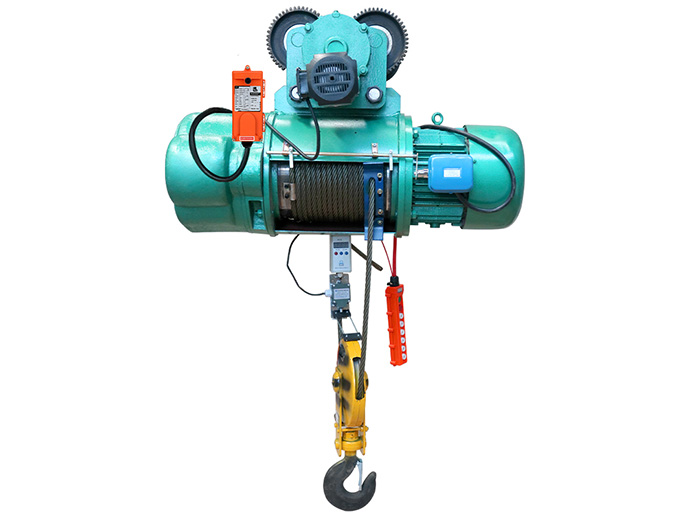

Superior operational performance is key to boosting efficiency. Modern cranes should be equipped with user-friendly control systems, intuitive interfaces, and increasingly integrated automation and intelligent functions (such as precise positioning, automatic anti-sway), to reduce operational difficulty and improve handling accuracy and turnaround speed. Safety is paramount. The equipment must incorporate multiple safety devices, including but not limited to overload protection, travel limiters, windproof and anti-slip devices, emergency stop systems, and comprehensive audio-visual alarm systems, ensuring minimal safety risks under all working conditions.

3. Evaluating Maintenance Convenience and Lifecycle Cost

Reliable equipment depends on convenient maintenance. Selection should focus on the crane’s maintainability design, such as modular structure, easy access to key components, and standardized common parts, which can significantly reduce routine maintenance time and repair costs. Choosing a manufacturer with a strong after-sales service network, capable of providing timely technical support and spare parts supply, is crucial. Furthermore, the total cost of ownership over the equipment’s lifecycle should be assessed, including energy consumption, periodic maintenance, overhauls, and potential upgrade expenses.

4. Balancing Energy Efficiency and Environmental Adaptability

With the growing emphasis on green port concepts, the energy efficiency performance of cranes is increasingly important. Electric or hybrid power systems are generally more energy-efficient and environmentally friendly than traditional diesel power, offering lower long-term operating costs. Port environments often face corrosive challenges like sea breezes, salt spray, and humidity. The crane structure should feature high-level anti-corrosion treatment (e.g., heavy-duty coatings, stainless-steel components), and electrical systems require corresponding protection ratings to ensure long-term stability and reliability in harsh weather conditions.

5. Considering Technological Advancement and Future Expandability

In today’s era of rapid technological development, considering the equipment’s advancement is equally important. Factors such as support for remote monitoring, fault diagnosis, data collection and analysis (IoT functions), and the ease of future upgrades to semi-automatic or fully automatic operation modes are all related to the port’s long-term competitiveness and intelligence level.

Selecting gantry cranes for a port terminal is a decision fundamental to its operations. A rigorous comprehensive evaluation must be conducted from multiple dimensions: the terminal’s actual conditions, operational demands, safety standards, economic benefits, and future development. Through meticulous planning and selection, ports can invest in the most suitable equipment, thereby ensuring safe, efficient, economical, and sustainable terminal operations.