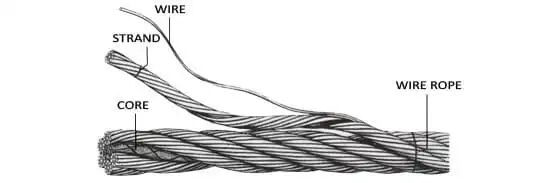

The steel wire ropes of cranes are regarded as consumable components. We need to properly maintain them to ensure their service life and durability. Their safety and long-term use depend on the maintenance they receive.

This article covers 6 main parts: loading and unloading of steel wire ropes, storage, pre-installation, installation, commissioning, maintenance, and replacement.

Wire Rope Storage & Handling

- Handle with care during unloading to prevent accidents and damage.

- Avoid dropping reels/coils or using metal forks/hooks that may deform the rope.

- Store indoors in dry, cool areas, elevated from the floor. Keep away from chemicals and corrosive fumes.

- If outdoor storage is unavoidable, cover ropes to protect against moisture.

- Inspect stored ropes regularly for corrosion. Reapply compatible lubricant or anti-corrosive agent as needed.

- Rotate reels periodically in warm environments to prevent lubricant drainage.

Pre-installation Inspection

- Verify rope specifications and certificates upon receipt.

- Ensure the minimum breaking force meets crane manufacturer requirements.

- Measure and record new rope diameter (dm) in a tension-free straight section.

- For long-stored ropes, conduct visual and MRT inspections for corrosion.

- Check all sheaves and drum grooves

- Ensure proper fit for new rope size.

- Confirm no irregularities (e.g., corrugation) and adequate remaining thickness.

- Groove diameter should exceed nominal rope diameter by 5%–10%. For optimal performance, groove diameter should be ≥1% larger than actual rope diameter.

Rope Installation

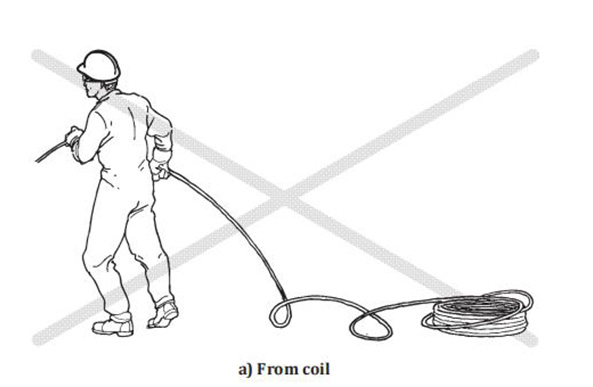

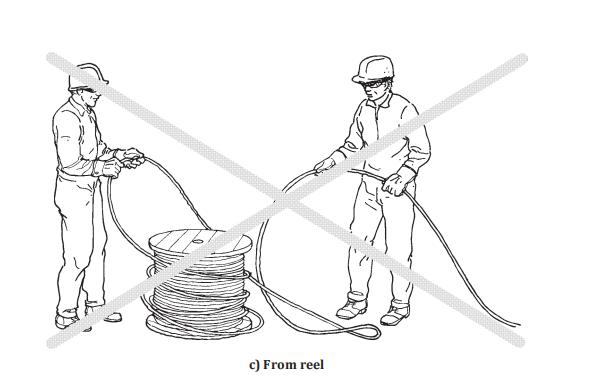

- Follow installation procedures strictly to avoid reeling issues that may cause loops, kinks, or bends.

- Unspool rope in a straight line with minimal slack.

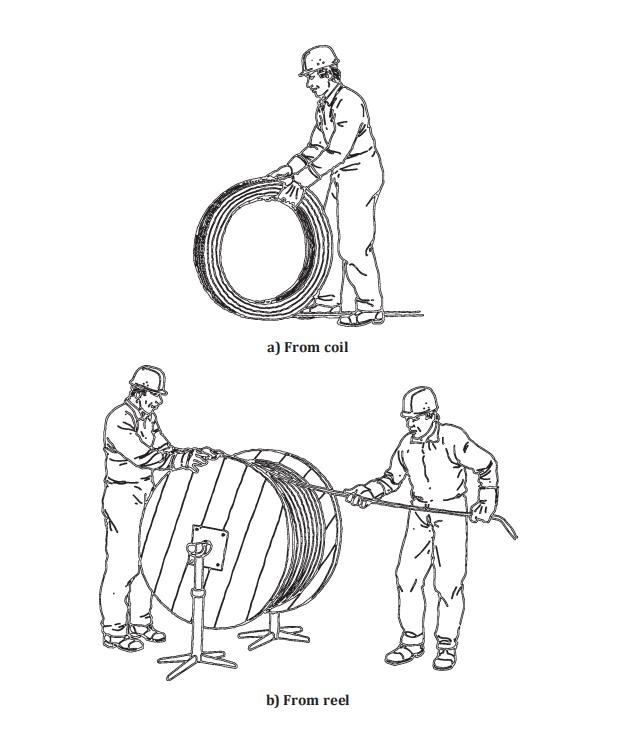

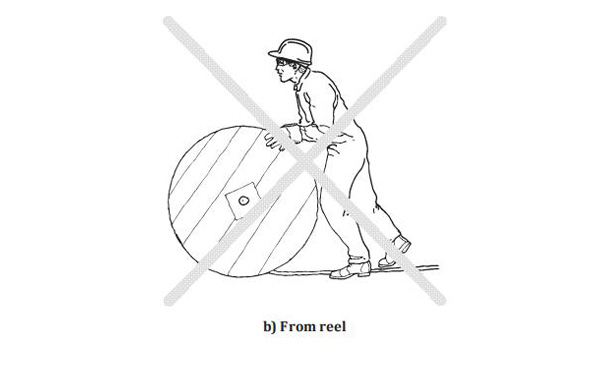

- For reeled ropes: Use a turntable for direct payout. For shorter lengths, release the outer end and roll the coil along the ground.

When the coil or reel is placed flat on the ground, the rope must not be released by swinging the wrapped object or rolling the reel along the ground.

Running-in of New Wire Rope

- Before putting the wire rope into full service, ensure all lifting limiters and indicators on the crane are functioning properly.

- To allow the rope components to adapt to normal operating conditions, the crane should be operated for multiple cycles at reduced speed and with a load not exceeding 10% of the Working Load Limit (WLL).

Wire Rope Maintenance

- Maintenance should be carried out based on crane type, frequency of use, environmental conditions, and rope type.

- Throughout its service life, the rope should be periodically inspected by a competent person, especially at sections passing over sheaves and drums, and near compensating sheaves. If signs of drying or corrosion are found, dressing should be applied promptly. Cleaning may be required before dressing for effectiveness.

- The dressing used must be compatible with the rope manufacturer’s original lubricant and possess good penetrating properties. If the crane manual does not specify the dressing type, consult the rope supplier or manufacturer.

- Lack of maintenance can shorten rope life, especially in corrosive environments or when dressing cannot be applied regularly. In such cases, inspection intervals should be shortened accordingly.

- If broken wires are concentrated near or at an end fitting while the rest of the rope remains in good condition, the damaged section may be cut off and a new end fitting installed. Before doing so, verify that the remaining rope length retains the minimum required number of wraps on the drum at the farthest operating limit.

Wire Rope Replacement

- Only wire rope specified by the crane manufacturer—or approved by the manufacturer, rope maker, or other qualified person—with the correct length, diameter, construction, type, lay, and strength (minimum breaking force) shall be installed. Replacement records must be kept on file.

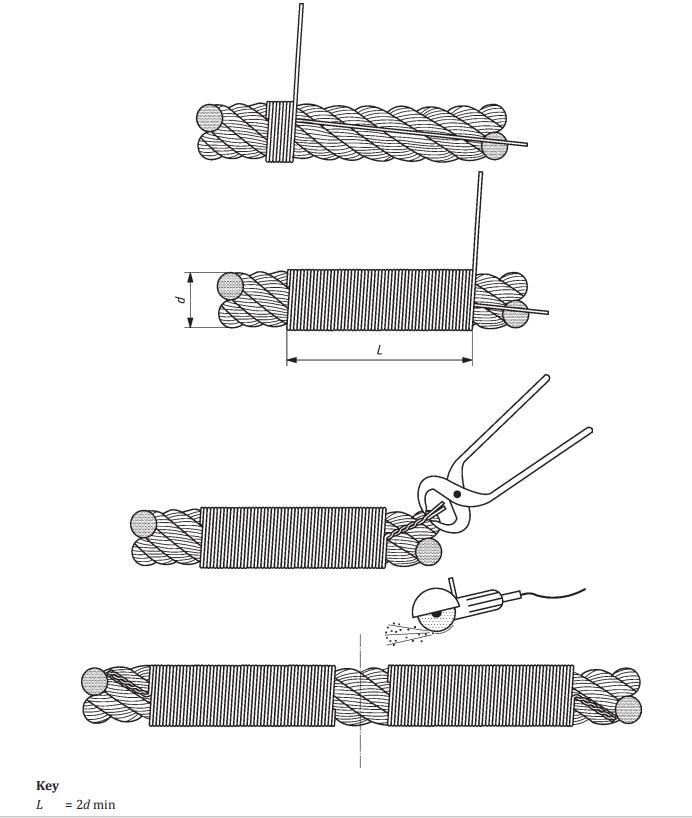

- For larger-diameter or rotation-resistant ropes, additional methods such as steel strapping or banding may be required to secure rope ends, particularly when preparing test samples.

- If the required rope length is cut from a longer coil or reel, secure both sides of the intended cut point with binding to prevent the rope from unraveling after cutting.