In industrial handling, warehouse loading/unloading, outdoor construction, and other scenarios, flexible and efficient lifting equipment is often required. Portable gantry cranes, with their unique advantages, have become an ideal choice for many applications. This article provides a comprehensive overview of this practical lifting tool from multiple perspectives.

1. Definition and Basic Structure

1.1 Definition

A portable gantry crane, also known as a portable gantry, is a flexible, movable, and easily assembled lifting device used for short-distance handling of small to medium-sized loads. Unlike large fixed cranes, it requires no complex foundation construction and can be quickly deployed across different work sites as needed.

1.2 Basic Structure

Its core components include:

- Main BeamTypically made of high-strength steel, it bears the load’s weight. Lengths can be customized or adjusted.

- LegsFixed or adjustable legs provide stability. Some models feature casters for mobility.

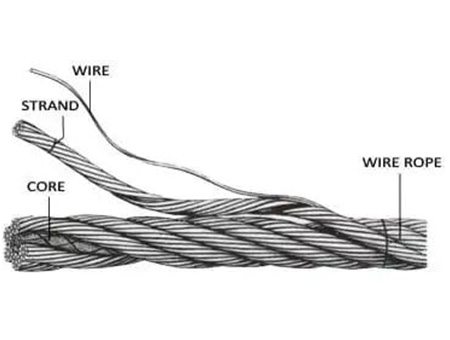

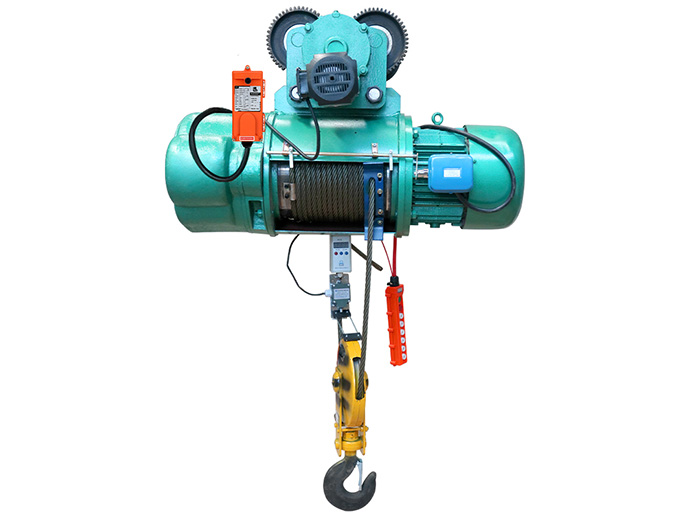

- Lifting System Consists of a hoist (manual or electric), wire rope, and hook for lifting and lowering.

- Control SystemElectric models come with control buttons or remote controls; manual types use hand-crank mechanisms.

2. Working Principle

The portable gantry crane operates based on mechanical balance and simple machinery principles:

- Position the crane, adjust leg height to ensure the beam is level and stable.

- Lower the hook and securely attach it to the load.

- Operate the hoist to lift the load slowly, avoiding collisions.

- Move the crane (manually or via drive) to the target location and lower the load.

3. Advantages and Applications

3.1 Key Advantages

- High FlexibilityCompact and lightweight, often equipped with casters for easy movement in tight spaces.

- Easy AssemblyModular design allows quick setup or disassembly by 2–3 people.

- Cost-EffectiveLower purchase and maintenance costs compared to large cranes, with no foundation expenses.

- Wide AdaptabilitySuitable for indoor workshops, warehouses, outdoor sites, and labs.

3.2 Typical Applications

- Factory workshops (machine tools, molds)

- Warehouse logistics (loading/unloading)

- Outdoor construction (material handling)

- Laboratories (precision instrument relocation)

- Temporary sites (events, installations)

4. Selection Tips and Recommendations

- Determine Load CapacityChoose a model with a rated load slightly above your typical requirements.

- Consider WorkspaceMeasure available width, height, and length to select appropriate beam span and lifting height.

- Choose Drive TypeElectric for heavy/frequent use; manual for light/occasional tasks.

- Check Material QualityOpt for high-strength steel with anti-rust treatment.

- Verify Safety FeaturesLook for overload protection, limit switches, and reliable braking systems.

5. Safety Usage Guidelines

- Inspect before useCheck wire rope, hook, legs, and controls for damage.

- Never overloadStrictly adhere to rated capacity.

- Keep clearEnsure no one stands under the load during operation.

- Avoid harsh weatherDo not operate outdoors in strong wind, rain, or lightning.

- Secure after useRaise the hook, power off, and store in a designated area.

6. Maintenance and Care Guidelines

- Regular CleaningWipe down surfaces and clear debris from casters weekly.

- LubricationMonthly lubrication of moving parts (bearings, axles).

- Component InspectionQuarterly checks of wire rope, hook, and bolt tightness.

- Proper StorageKeep indoors or covered outdoors; avoid damp conditions.

7. Comparison with Other Lifting Equipment

| Equipment Type | Pros | Cons | Best For |

|---|---|---|---|

| Portable Gantry Crane | Mobile, quick setup, low cost | Limited capacity (usually ≤10 tons) | Temporary/multi-site tasks |

| Fixed Gantry Crane | High capacity, stable, long-span | Requires foundation, immobile | Permanent high-volume sites |

| Forklift | Fast, good for palletized goods | Limited lift height, needs wide aisles | Horizontal transport, stacking |

| Jib Crane | Rotates, covers radial area | Limited coverage, lower stability | Workstation loading/unloading |

| Electric Hoist/Overhead | Simple, low cost, easy installation | Limited to rail/I-beam movement | Repetitive linear lifting tasks |

8. Conclusion

Portable gantry cranes offer flexibility, economy, and ease of use for small to medium lifting tasks. Proper selection, safe operation, and regular maintenance ensure safety, extend service life, and improve efficiency.

Note: Always follow the manufacturer’s instructions and local safety regulations for crane operation and maintenance.