Description

Heavy Duty & Efficient · Intelligent Control · Wind Resistant & Stable · Core Equipment for Large Scale Outdoor Handling

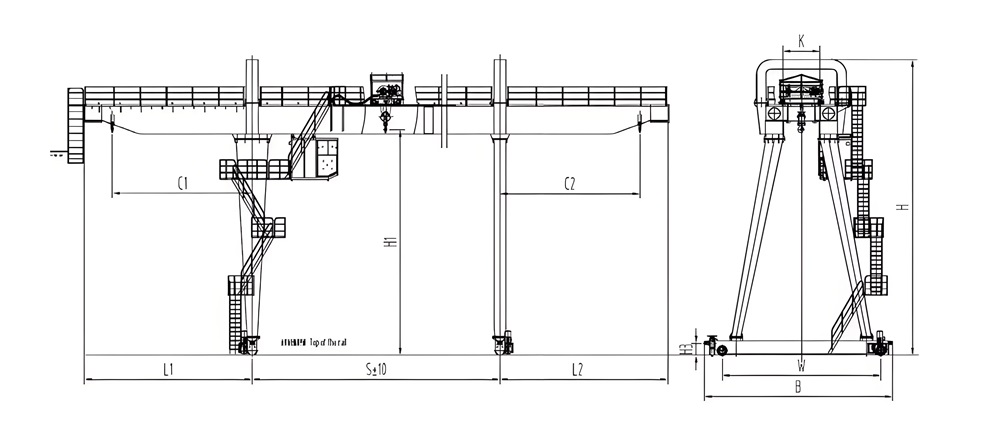

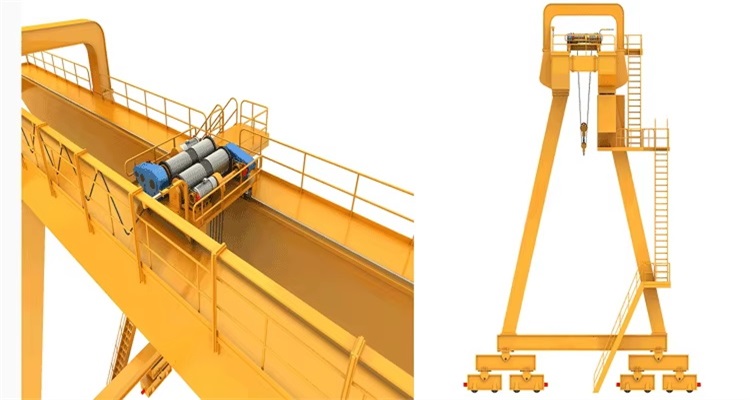

The MG A double girder gantry crane features a high strength box type double girder and an optimized A type leg structure. It offers large span, high lifting capacity, and continuous heavy load operation, making it suitable for outdoor heavy duty material handling in ports, railway freight yards, large storage yards, and heavy industrial zones. The crane integrates intelligent drive systems, precise positioning, and multiple safety systems, enabling efficient, stable, and reliable handling and stacking of large scale materials such as containers, steel products, and bulk cargo.

Advantages

Finite element optimized box type double girders support spans up to 10–35 m and rated loads of 5–500 t, with excellent wind and torsional resistance.

Full VFD multi mechanism synchronous control with automatic anti sway and precise positioning systems ensures smooth operation and positioning accuracy of ±10 mm.

Supports quick change over of hooks, grabs, electromagnetic lifters, container spreaders, etc., adapting to diverse material handling needs.

Integrated overload limiter, wind speed monitoring, 3D anti collision, video tracking, and remote diagnostics.

High efficiency motors and energy recovery design reduce energy consumption by 25% compared to traditional gantry cranes, with a structural design life ≥30 years.

Customization Options

| Span & Lifting Height | Span: 10–35 m; lifting height: 6–20 m, with support for non standard large span and extra high lift designs. |

| Lifting Attachment System | Hooks, grabs, electromagnetic lifters, container spreaders, multi tine grabs, etc., with optional quick change and automatic docking systems. |

| Travel Mechanism Type | Double rail / single rail travel; tire mounted / rail mounted; |

| Electrical & Control | PLC + VFD control, remote centralized control, unattended automation systems, intelligent dispatch, and data management modules. |

| Safety & Environmental Configuration | Windproof anchoring, anti corrosion/explosion proof design, high temperature adaptation, video surveillance, laser anti collision, wind speed alarm systems. |

| Structural Variants | A type legs, L type legs, dual trolley cooperation, auxiliary hook systems, etc. |

Why Choose Us?

| 15+ Years of Expertise | We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology. |

| Certified Quality | All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards. |

| Tailored to Your Needs | Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments. |

| Strong Customization Engineering Capability: | Undertake non standard, oversized, and complex condition gantry crane projects, providing end to end services from design and manufacturing to installation and commissioning. |

| End-to-End Support | We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle. |

We provide structural selection, lifting attachment configuration, intelligent control system integration, and full lifecycle operational support based on your material characteristics, workflow, site conditions, and automation goals. Please share your project parameters or schedule an on site survey—we will build a safe, efficient, and intelligent heavy duty handling system for you.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.