Description

Precision Bearing · Flexible Drive · Intelligent Integration · High-Reliability Operating Solution

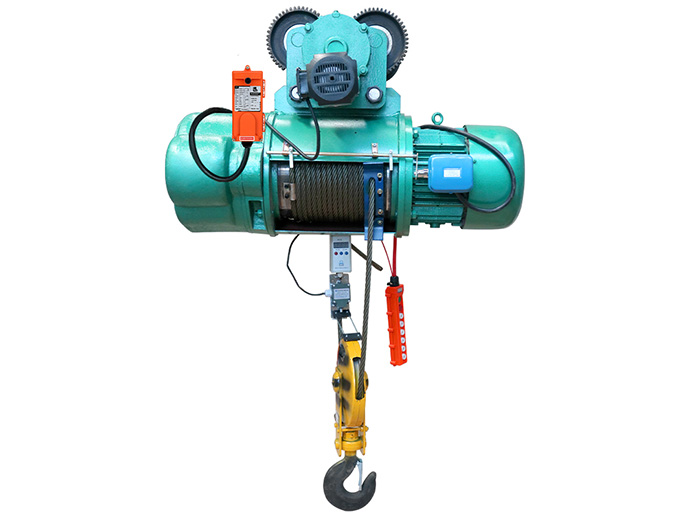

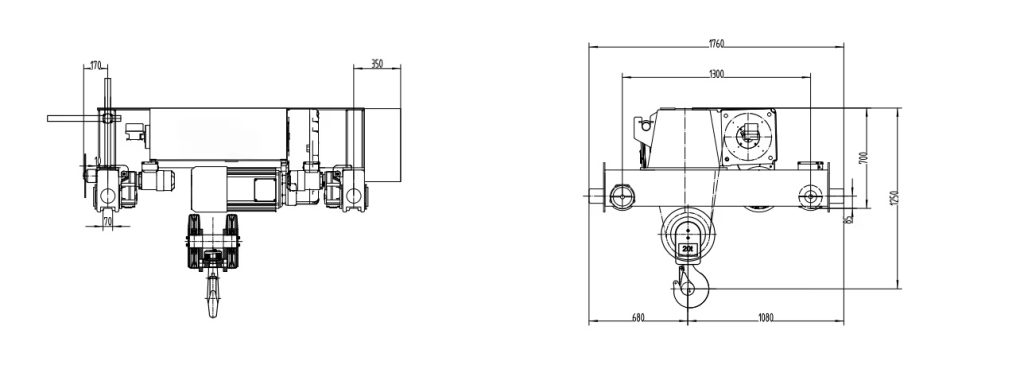

The double-girder European-style trolley is a precision traveling mechanism specifically designed for heavy-duty industrial applications. Adopting European modular design principles, it integrates a three-in-one drive unit, compact structure, and adaptive control system. This product can be paired with various double-girder overhead cranes and gantry cranes, making it suitable for heavy-load handling scenarios with stringent requirements for positioning accuracy, operational stability, and long-term reliability. It serves as a core traveling execution unit in fields such as heavy manufacturing, energy equipment, and logistics hubs.

Advantages

Three-in-one geared motor direct drive, transmission efficiency >95%, compact structure, easy maintenance.

Supports variable frequency stepless speed control, smooth start/stop, repeat positioning accuracy up to ±2mm.

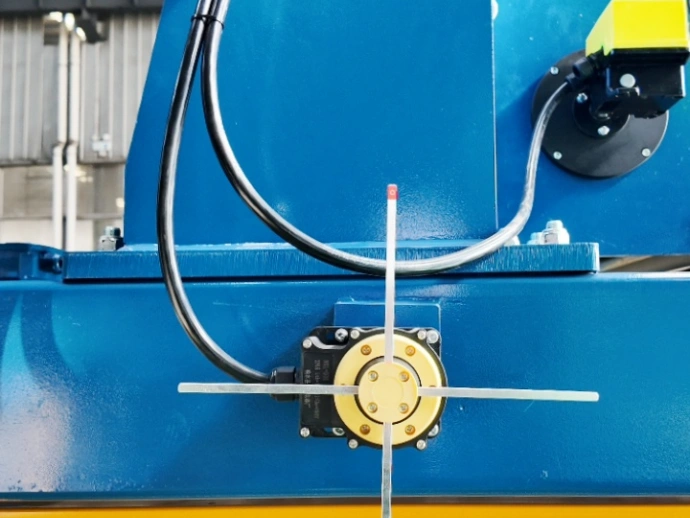

Built-in load monitoring, anti-collision sensing, temperature monitoring, and fault self-diagnosis systems.

Core components made of high-strength alloy steel and wear-resistant coating, design life ≥20 years, long maintenance-free period.

Protection rating up to IP65, suitable for complex conditions including temperatures from 20℃ – 40℃, high humidity, and dusty environments.

Application

- Heavy Equipment ManufacturingWind turbine blade assembly, pressure vessel handling, precise positioning of large structural components.

- Energy & Power IndustryHydraulic turbine installation, nuclear power equipment maintenance, heavy component handling in substations.

- Port & Yard OperationsContainer loading/unloading, bulk cargo grabbing, multimodal lifting systems.

- Steel & Non-Ferrous MetalsMolten steel ladle transfer on continuous casting platforms, rolling line roll replacement, high-temperature material handling.

- Automated Storage SystemsHeavy-duty storage retrieval in high-bay warehouses, heavy material interface transfer for production lines.

Specification

| Capacity(t) | Working class | Lifting height (m) | Lifting speed (m/min) | running velocity (m/min) | Rope reeving |

| 10 | M5 | 6 | 5/0.8 | 2-20 | 4/1 |

| 9 | |||||

| 12 | |||||

| 15 | |||||

| 18 | |||||

| 16 | M5 | 9 | 4/0.67 | 2-20 | 4/1 |

| 12 | |||||

| 15 | |||||

| 18 | |||||

| 32 | M5 | 8 | 2.7/0.45 | 2-20 | 6/1 |

| 10 | |||||

| 12 | |||||

| 16 | |||||

| 50 | M5 | 6 | 0.53/3.2 | 2-20 | 12/2 |

| 9 | |||||

| 12 | |||||

| 12 |

Customization Options

5t – 200t, supports non-standard load design and verification.

2 – 30 m/min (adjustable via VFD), micro-speed down to 0.5 m/min.

QU-type / P-type steel rails; customized interfaces for heavy box girders / I-beams.

Single drive / dual drive / quad drive; explosion-proof motors / high-altitude motors / low-temperature start motors available.

Conventional relay / PLC control / bus integration (Profibus, CANopen, etc.).

Laser anti-collision / wind speed monitoring / tilt protection / remote weight data transmission.

Standard / low headroom / side-slung / dual-trolley cooperative types.

5G communication module / remote diagnostic port / digital twin data interface / automatic lubrication system.

Why Choose Us?

| 15+ Years of Expertise | We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology. |

| Certified Quality | All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards. |

| Tailored to Your Needs | Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments. |

| 100% Tested Before Delivery | Every unit undergoes rigorous testing prior to shipment, guaranteeing stable performance and safety compliance. |

| End-to-End Support | We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle. |

Technical Collaboration & Consultation

provide trolley selection calculations, rail compatibility analysis, and intelligent control integration solutions based on your crane system parameters, operational scenarios, and automation needs. Please provide operational drawings or schedule a technical discussion—we will develop a highly reliable, scalable traveling system solution for you.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.