Description

Compact Design · Intelligent Control · High Safety Standards · Modular Configuration

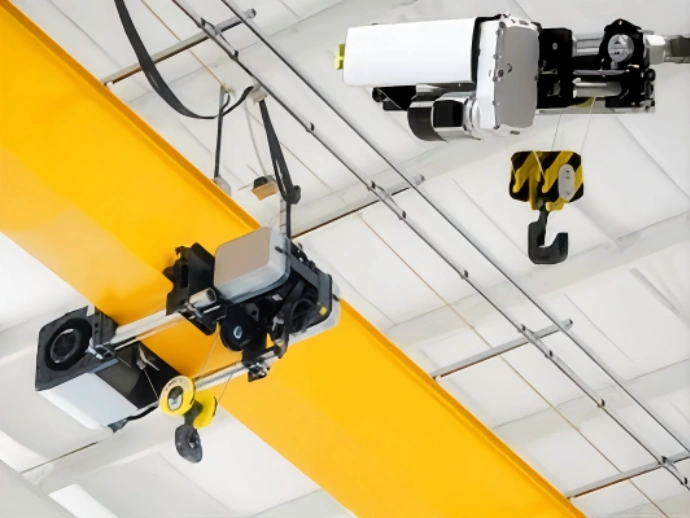

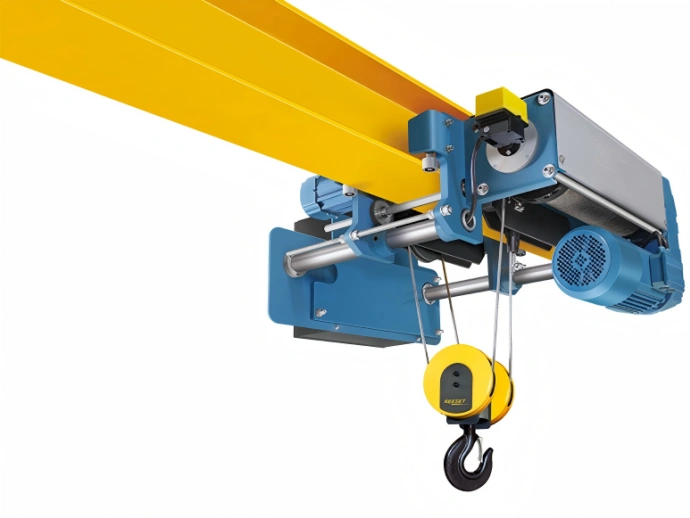

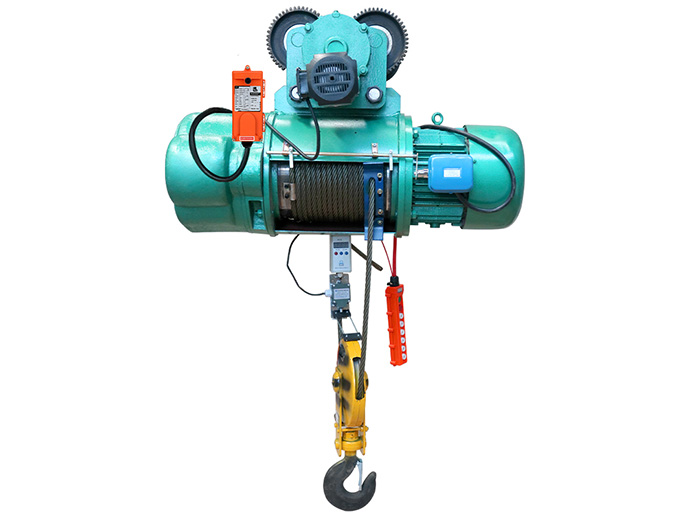

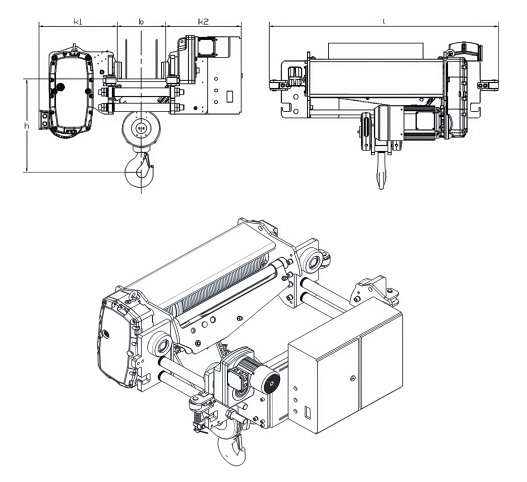

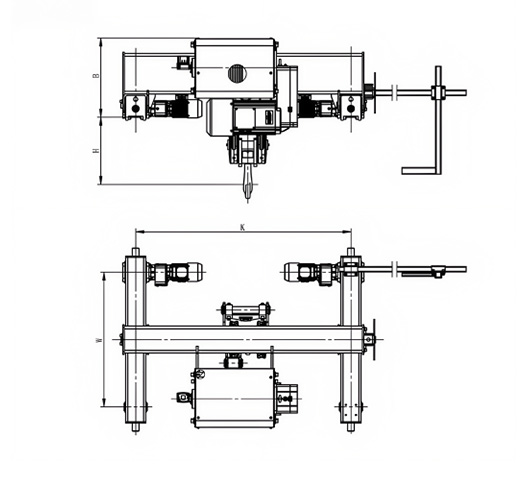

The European-style electric hoist incorporates leading European design concepts and manufacturing technologies, integrating a compact structure, efficient transmission, and intelligent control. Key features include a lightweight bridge structure, low headroom design, and high-precision lifting, making it suitable for industrial applications that demand high space utilization, smooth operation, and long-term reliability. This product series is widely compatible with single- and double-girder overhead cranes, suspension systems, and custom lifting equipment, meeting the efficient hoisting needs of modern production lines, logistics centers, cleanrooms, and other diverse scenarios.

Advantages

Low headroom design maximizes space utilization; modular components enable easy installation and maintenance.

Frequency conversion control ensures smooth start/stop; optimized gear transmission reduces noise and vibration.

Integrated overload protection, limit control, and real-time monitoring; supports remote diagnostics and fault alerts.

High-efficiency motor and energy recovery system reduce power consumption; compliant with CE, ISO, and EU lifting machinery safety directives.

High-strength steel and wear-resistant components; protection rating up to IP55/IP65, suitable for harsh environments such as dust, humidity, and more.

Specification

| Capacity(t) | Workingclass | Lifting height(m) | Lifting speed(m/min) | running velocity(m/min) | Lifting power(kw) | operating powe(kw) |

| 3 | M5 | 6 | 5/0.8 | 2-20 | 3.2 | 0.44 |

| 9 | ||||||

| 12 | ||||||

| 15 | ||||||

| 18 | ||||||

| 5 | M5 | 6 | 5/0.8 | 2-20 | 4.9 | 0.44 |

| 9 | ||||||

| 12 | ||||||

| 15 | ||||||

| 18 | ||||||

| 21 | ||||||

| 10 | M5 | 9 | 5/0.8 | 2-20 | 9.8 | 0.96 |

| 12 | ||||||

| 15 | ||||||

| 18 | ||||||

| 24 |

Applications

Smart Manufacturing & Automotive Industry

Used in automotive assembly lines, component handling, welding stations, etc., supporting high-tempo, high-precision lifting operations.

Logistics Warehousing & Distribution Centers

Suitable for high-bay storage retrieval, container loading/unloading, and production line interface transfers, improving logistics efficiency.

New Energy & Aerospace

Used in wind turbine blade assembly, battery module handling, aircraft component maintenance, and other scenarios requiring high cleanliness and precision.

Food, Pharmaceutical & Cleanroom Environments

Stainless steel options and dust-free design comply with GMP/HACCP and other industry hygiene standards.Heavy Equipment & Construction Engineering

Supports heavy-duty operations such as large machinery installation, steel structure lifting, and ship maintenance.

Customization Options

| Lifting Capacity | 0.5t – 32t, with support for non-standard tonnage customization. |

| Lifting Height | 3m – 30m, adaptable to different facility structures. |

| Control Method | Pendant control / wireless remote control / smart integration (with MES/PLC systems). |

| Operating Speed | Single speed / dual speed / variable frequency speed control, supporting precise positioning and micro-motion operations. |

| Power Supply & Voltage | 220V/380V/460V, 50/60Hz, compatible with global voltage standards. |

| Protection & Material | IP55/IP65 protection rating; carbon steel / stainless steel / explosion-proof / high-temperature resistant coating options. |

| Installation Method | Fixed type / low building height type / double-girder trolley type / wall-mounted type. |

| Smart Function Expansion | Load monitoring / anti-sway system / automatic positioning / remote maintenance interface / data logging and analysis modules. |

Why Choose Us?

| 15+ Years of Expertise | We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology. |

| Certified Quality | All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards. |

| Tailored to Your Needs | Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments. |

| 100% Tested Before Delivery | Every unit undergoes rigorous testing prior to shipment, guaranteeing stable performance and safety compliance. |

| End-to-End Support | We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle. |

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.