Description

Compact & Efficient · Intelligent Control · Modular Design · Energy-Saving & Reliable

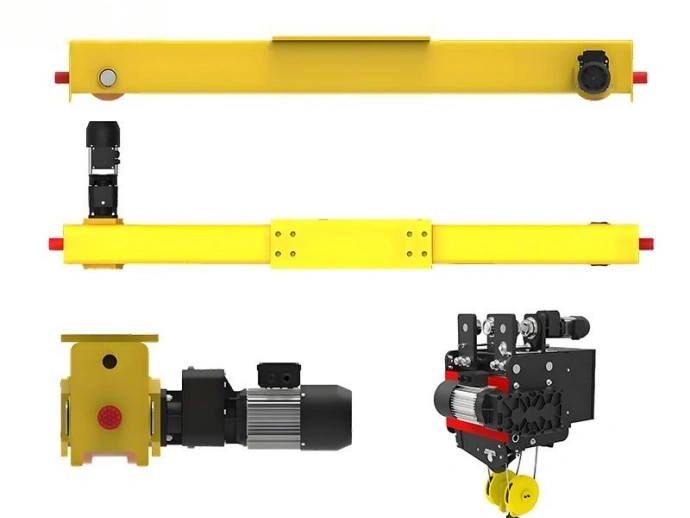

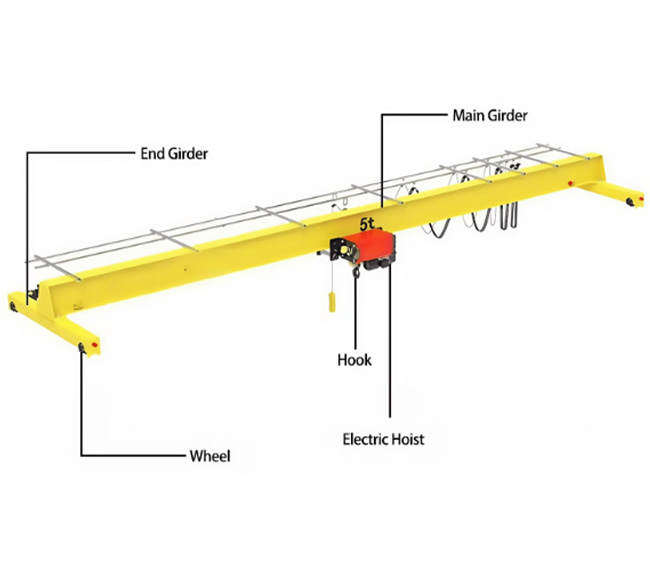

The European single-girder overhead crane adopts a lightweight European design philosophy, integrating a high-strength box-type main girder, a three-in-one drive system, and intelligent control technology. Featuring a compact structure, light weight, smooth operation, and low energy consumption, this product is ideal for modern workshops, warehouses, and production lines that demand high space efficiency, operational precision, and energy savings. It serves as an optimal solution for medium to small-tonnage material handling.

Advantages

Optimized box-type girder structure reduces weight by 25%–30% compared to traditional cranes, minimizing structural load on the building.

Fully variable frequency control ensures shock-free start/stop and positioning accuracy of ±5mm; supports adaptive speed adjustment.

Modular design of drive, electrical, and traveling systems allows quick disassembly and replacement, reducing maintenance costs.

High-efficiency motors and energy recovery systems reduce overall energy consumption by over 30%, meeting green factory standards.

Equipped with multiple limit switches, anti-collision systems, overload protection, and real-time monitoring; certified to CE/ISO standards.

Application

- Manufacturing Assembly Workshops

- Warehousing & Logistics Centers

- Food & Pharmaceutical Industries

- Light Industry & Electronics

- Maintenance & Service Areas

| Lifting Capacity | 1t-16t |

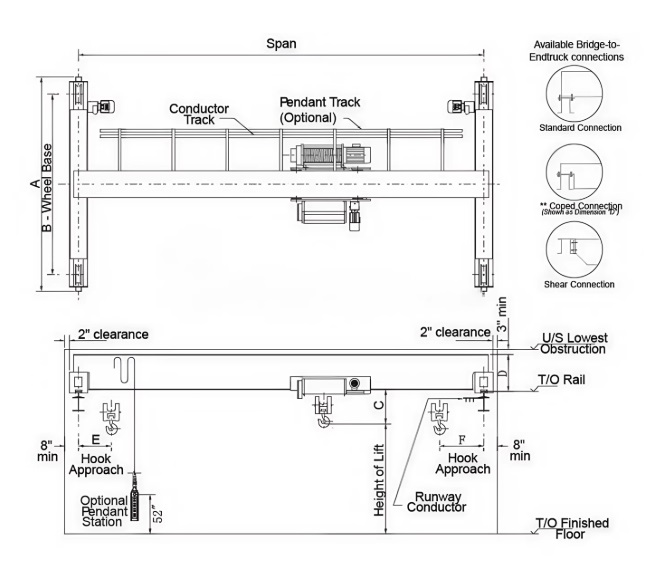

| Span | 3m~22.5m |

| Lifting Height | 6m~24m |

| Lifting Speed | 5/0.8m/min |

| Long traveling speed | 3~30m/min |

| Cross traveling speed | 1~00m/min |

| Power supply | AC 380V 50Hz |

| Working Class | A5 |

Customization Options

| Rated Lifting Capacity | 1t – 16t, with support for non-standard tonnage customization |

| Span Range | 3m – 22.5m, optimized according to actual workshop span. |

| Lifting Height | 6m – 24m, with customization for low headroom or extra-high lifting. |

| Operating Speed | Variable frequency stepless speed control; bridge speed: 3 – 30 m/min, trolley speed: 1 – 10 m/min. |

| Control Method | wireless remote control / cabin operation / intelligent dispatch system (integration with MES/WMS). |

| Electrical Configuration | Siemens/Schneider electrical systems; supports global voltages; optional explosion-proof and corrosion-resistant ratings. |

| Rail Type | Light-duty rails / heavy-duty rails / suspended rails, adaptable to different workshop structures. |

| Intelligent Extensions | Precision positioning system / anti-sway control / load monitoring / remote maintenance interface |

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards.

Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments.

Every unit undergoes rigorous testing prior to shipment, guaranteeing stable performance and safety compliance.

We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle.

Technical Consultation & Solution Design

We provide crane selection calculations, rail layout optimization, and intelligent control integration solutions based on your workshop layout, usage frequency, load characteristics, and automation needs. Please share your facility drawings or schedule an on-site survey—we will design a cost-effective European-style crane solution tailored to your requirements.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.