Description

Lightweight Design · Modular Integration · Flexible Deployment · Intelligent Human-Machine Collaboration

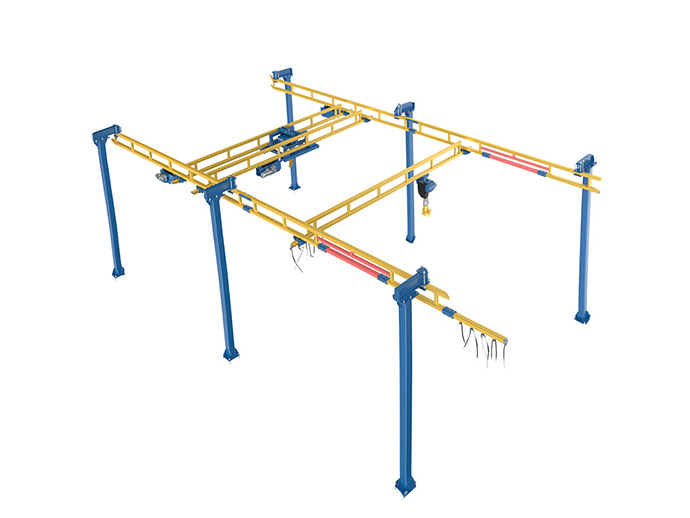

The KBK flexible crane system is a lightweight lifting solution based on standardized modular components. Utilizing an overhead track suspension structure, it can be flexibly configured into linear, curved, or circular transport paths according to spatial layouts. Comprising tracks, trolleys, suspension devices, and electrical control units, the system features low weight, fast installation, and high scalability, making it suitable for precise handling of small to medium loads, material transfer on assembly lines, and multi-station collaborative operations.

Advantages

Standard components support combinations of any length, angle, or height, allowing rapid reconfiguration as production layouts change.

Aluminum alloy tracks and lightweight structures reduce load requirements on buildings, with energy consumption lowered by over 50% compared to traditional cranes.

Equipped with servo drives and encoder positioning systems, achieving repeat positioning accuracy of ±1mm and supporting fine micro-motion alignment.

Manual push/pull resistance ≤10N, featuring fall protection and collision buffers for safe operation in human-machine mixed environments.

Bolt-connected design eliminates welding needs, reducing installation time by 70%; components can be replaced independently for easy maintenance.

Application

- Automotive Assembly LinesFlexible assembly tasks such as dashboard installation, door panel transfer, and powertrain precise docking.

- Electronics & Electrical ManufacturingCircuit board flow, precision component assembly, and material transfer between inspection stations.

- Medical Device ProductionMaterial distribution in sterile workshops, surgical equipment assembly, and light-load handling on packaging lines.

- Light Industrial Consumer GoodsHome appliance assembly, furniture component transfer, and material rotation on cosmetic filling lines.

- Research & LaboratoryExperimental equipment lifting, sample positioning and transfer, and material handling in clean environments

Customization Options

| Load Capacity & Span | Single-point load: 0.25– 3Ton ; main beam span: 1m – 30m, with support for multi-beam parallel systems. |

| Track Layout | Straight tracks / curved tracks (horizontal/vertical turns) / switch systems / 3D spatial network layouts. |

| Power Mode | Manual push / pneumatic assist / electric drive (VFD/servo) / automated guided (AGV docking). |

| Control Method | Manual control / wireless remote control / intelligent fixed-point transfer / integration with MES/PLC systems. |

| Lifting Attachment Compatibility | Vacuum lifters / mechanical grippers / balancers / rotating hooks / weighing detection modules. |

| Safety Expansion Features | Load display / height limiters / restricted zones / safety light curtains / audible-visual warning systems. |

| Environmental Adaptation | Cleanroom models (dust-free, anti-static) / corrosion-resistant coatings / explosion-proof configurations / food-grade materials. |

Why Choose Us?

- Full-Range In-House Production Capability | Complete control from track extrusion to electrical system integration ensures quality and delivery reliability.

- Extensive Flexible System Integration Experience | Over 300 flexible production line crane solutions delivered across automotive, electronics, medical, and other industries.

- Rapid Response Design Capability | Supports 3D layout simulation and load modeling, with customized proposals and quotations provided within 5 working days.

- Full-Cycle Service Network | Offers layout planning, installation training, direct spare parts supply, and system upgrade services for long-term technical collaboration.

We provide crane selection calculations, rail layout optimization, and intelligent control integration solutions based on your workshop layout, usage frequency, load characteristics, and automation needs. Please share your facility drawings or schedule an on-site survey—we will design a cost-effective European-style crane solution tailored to your requirements.

Solution

Based on your workshop space, process flow and cycle time requirements, we offer KBK system layout design, load simulation and intelligent control integration solutions. Please share your facility drawings or video conference – we will create for you a highly flexible and efficient lightweight material handling system.