Description

Lightweight Design · Modular Structure · Intelligent Control · Cost-Effective Solution

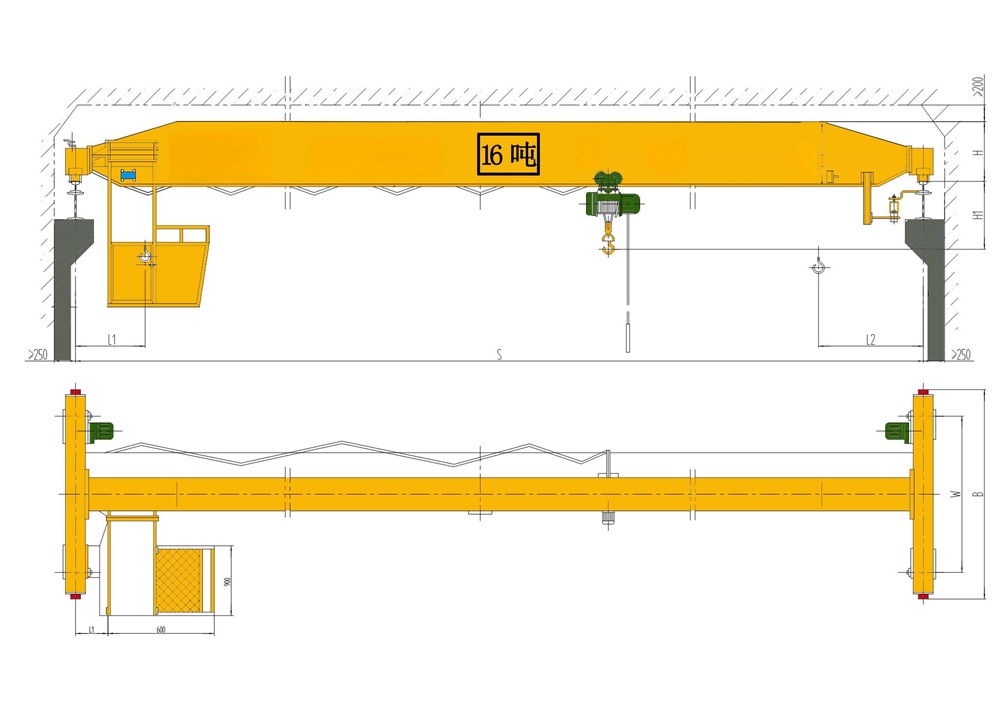

Electric bridge crane is a kind of rail running, small single girder structure lifting equipment, easy to install, cost-effective. It is often used in conjunction with CD1/MD1 electric hoist, and is widely used for loading and unloading and carrying objects in machining workshops, warehouses and other places.

Advantages

Optimized box-type girder design reduces weight by 15%-20%, lowering structural load on the building.

Integrated three-in-one drive ensures smooth starting and precise positioning; variable frequency drive (VFD) options improve accuracy and efficiency.

Modular design enables quick on-site assembly; key components are easily accessible for fast maintenance.

Includes overload protection, dual limit switches, emergency braking, and audible/visual alarms, complying with national crane safety standards.

Supports smart crane management systems for real-time monitoring, fault alerts, and data logging.

Application

- Manufacturing Workshops: Component handling, semi-finished assembly, equipment maintenance

- Warehousing & Logistics Centers: Material storage/retrieval, loading/unloading, internal transport

- Light Industry Assembly Lines: Lifting solutions for electronics, packaging, and light industrial production

- Maintenance & Service Areas: Flexible lifting support for equipment repair and mold replacement

- Small & Medium-Sized Factories: Cost-effective lifting for intermittent or low-frequency use

Customization Options

| Lifting Capacity | 1t – 32t, with non-standard tonnages available upon request |

| Span | 3m – 22.5m, custom spans supported |

| Lifting Height | 7m – 30m, adjustable to actual workshop height |

| Operating Speed | Standard speed / variable frequency drive; trolley and bridge speeds customizable |

| Control Method | Pendant / remote control / cabin operation / automated integration (with production lines) |

| Electrical Components | Domestic quality brands / international brands; voltage options: 380V/415V/440V, etc. |

| Environmental Adaptation | Standard workshop / dust-proof / corrosion-resistant / high-temperature environments |

| Additional Functions | Weighing system / positioning system / anti-sway control / remote maintenance interface |

| Crane travelling mechanism | Travelling speed(m/min) | 20/30 | ||

| Power(KW) | 0.8*2,1.5*2,2*2.2 | |||

| Lifting&travelling mechanism | Travelling speed(m/min) | 20/30 | ||

| Hoist type | CD/MD | Lifting speed(m/min) | 6-30 | |

| Capacity(t) | 1-32 | Lifting height(m) | 8,7,35 | |

| Span(m) | 7.5~31.5 | |||

| Power Supply | AC 380V 50Hz | |||

| Wheel diameter | Φ250,Φ315 | |||

| Work Grade | A4 | |||

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards.

Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments.

Every unit undergoes rigorous testing prior to shipment, guaranteeing stable performance and safety compliance.

We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.