Description

Flexible Layout · Material-Efficient · Intelligent Positioning · Multi-Scenario Adaptability

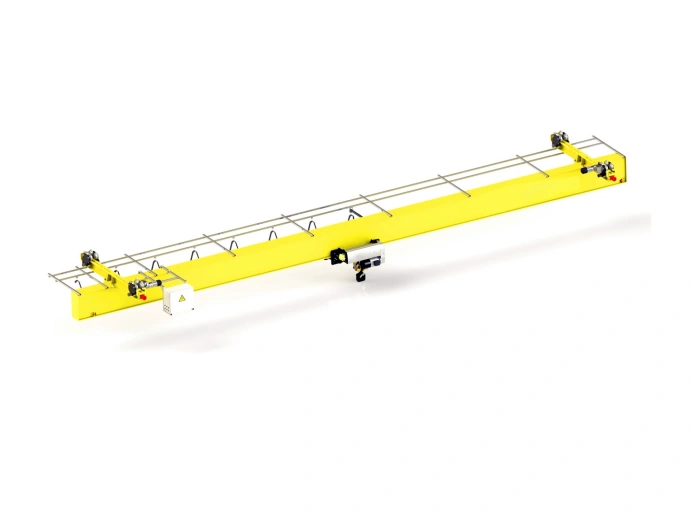

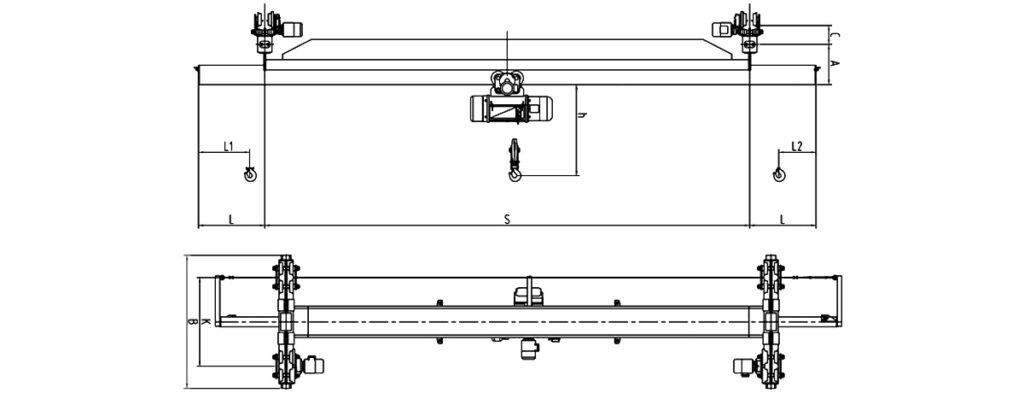

The underhung single-girder overhead crane features a top-mounted track suspension design, eliminating the need for support columns and allowing direct installation onto workshop roof structures or dedicated traveling rail systems. Lightweight in construction and flexible in installation, this crane maximizes the use of upper workshop space and is ideal for modern workshops and production lines that require high ground-space utilization and adaptable process layouts. With smooth operation, precise positioning, and versatile configurations, it serves as an efficient solution for medium- and light-duty material handling and production line workflows.

Advantages

No support columns required, freeing up ground-level work areas and enhancing space utilization.

Modular structure supports suspended track installation, wide adaptability, and short construction cycles.

Variable frequency control and precise positioning systems ensure stable operation, low noise, and positioning accuracy up to ±3mm.

Main girder made of high-strength structural steel with excellent bending and torsional resistance; reliable hoisting mechanism suitable for continuous operation.

Compatible with various lifting attachments, control systems, and safety devices to meet diverse industry and scenario needs.

Application

- Manufacturing Assembly Workshops

- Warehousing & Logistics Centers

- Food & Pharmaceutical Industries

- Light Industry & Electronics

- Maintenance & Service Areas

Paramater

| Lifting Capacity | 1t-16t |

| Span | 3m~22.5m |

| Lifting Height | 6m~24m |

| Lifting Speed | 5/0.8m/min |

| Long traveling speed | 3~30m/min |

| Cross traveling speed | 1~00m/min |

| Power supply | AC 380V 50Hz |

| Working Class | A4 |

Customization Options

| Rated Lifting Capacity | 1t – 16t, with support for non-standard tonnage customization |

| Span Range | 3m – 22.5m, optimized according to actual workshop span. |

| Lifting Height | 6m – 24m, with customization for low headroom or extra-high lifting. |

| Operating Speed | Variable frequency stepless speed control; bridge speed: 3 – 30 m/min, trolley speed: 1 – 10 m/min. |

| Control Method | wireless remote control / cabin operation / intelligent dispatch system (integration with MES/WMS). |

| Electrical Configuration | Siemens/Schneider electrical systems; supports global voltages; optional explosion-proof and corrosion-resistant ratings. |

| Rail Type | Light-duty rails / heavy-duty rails / suspended rails, adaptable to different workshop structures. |

| Intelligent Extensions | Precision positioning system / anti-sway control / load monitoring / remote maintenance interface |

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards.

Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments.

Every unit undergoes rigorous testing prior to shipment, guaranteeing stable performance and safety compliance.

We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle.

Technical Consultation & Solution Design

We can provide underhung crane selection calculations, track layout planning, and system integration recommendations based on your workshop structure, material characteristics, usage frequency, and automation needs. Please share your facility drawings or on-site operational information—we will tailor the optimal underhung crane solution for you.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.