Description

Safety Explosion-Proof · Heavy-Duty Reliability · Intelligent Monitoring · Specialized Lifting Solution for Hazardous Environments

The QB series explosion-proof overhead crane is a specialized lifting solution engineered for operation in flammable and explosive environments. All its motors and electrical components are manufactured in strict compliance with international explosion-proof standards and regulations, incorporating specially designed safety features to eliminate potential ignition sources.

The crane’s with an explosion-proof motor and enclosed casing, ensuring reliable operation where sparks or high temperatures could pose a risk. With a standard lifting capacity ranging from 5 to 100 tons, this crane is capable of meeting diverse material handling requirements across a variety of high-risk settings. This crane is ideally suited for applications involving flammable gases—such as acetylene, hydrogen, ethylene, and propane—as well as explosive atmospheres commonly found in petroleum refining, natural gas processing, chemical production, and related industries.

Advantages

All motors, hoisting mechanisms, and electrical systems are constructed with explosion-proof materials and structures, certified to Ex d IIC T4 international standards.

Compatible with various attachments including electromagnetic lifters, hooks, and C-hooks to meet diverse operational requirements.

Main and end girders are fabricated from high-quality welded steel; non-metallic components utilize anti-static materials to ensure intrinsic safety.

Modular design of explosion-proof motors enables quick assembly and disassembly, reducing downtime.

Includes load limiter for automatic power cut-off during overload; critical seals prevent ingress of dust and hazardous gases.

Supports both remote ground control and cabin operation, enhancing safety and visibility while minimizing operational risks.

Application

- Chemical IndustryHandling and transport of oil, gas, pesticides, and fertilizers in production, storage, and logistics processes.

- Military IndustryProduction and storage of hazardous materials such as ammunition and pyrotechnics.

- Pharmaceutical & Food ProcessingLifting in alcohol extraction areas and handling of raw materials or finished products in flour and dairy production.

- Steel IndustryHoisting and transporting raw materials or semi-finished products in steel mills.

- Coal Mining & Underground OperationsUse in coal mines or underground areas with high concentrations of methane or combustible dust.

- Warehousing & LogisticsLoading and unloading of flammable and explosive goods in hazardous material storage facilities.

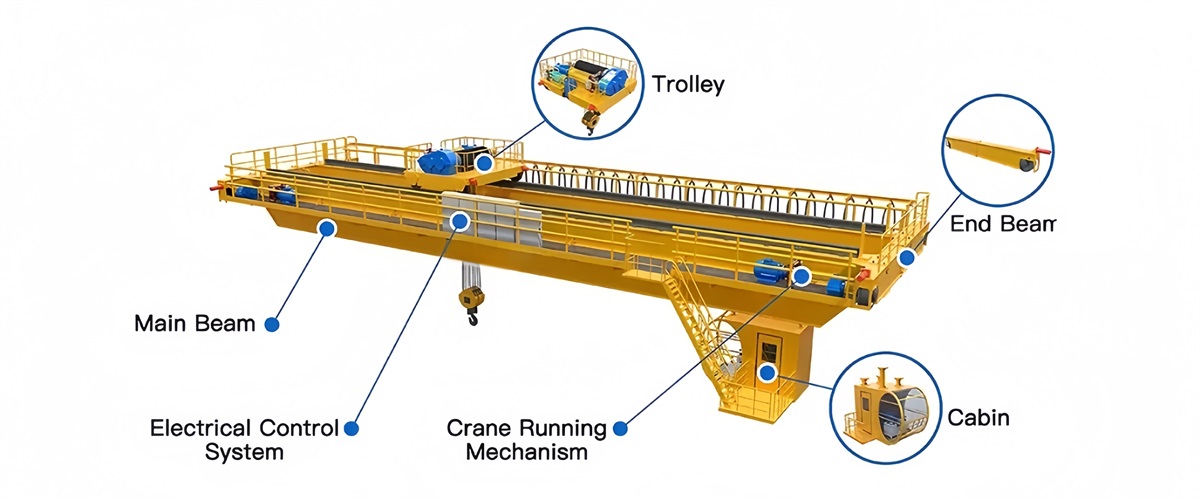

Structure & Functions

| Main Girder | Supports the trolley and bears both self-weight and lifting loads; designed with high strength, rigidity, and explosion-proof performance. |

| End Girder | Connects both ends of the main girder, supports the overhead traveling mechanism, and drives longitudinal movement of the crane. |

| Lifting Mechanism | Utilizes explosion-proof electric hoists or explosion-proof winch trolleys for vertical movement of goods. |

| Electrical System | Powered by explosion-proof busbars and explosion-proof cables to ensure safe electrical supply and signal transmission. |

| Safety Devices | Includes overload limiters, collision buffers, grounding devices, and other safety components for secure operation. |

| Control System | Operates via wireless remote control or explosion-proof cabin control, offering multiple operation modes. |

| Crane Spreader | Compatible with various attachments such as explosion-proof hooks, explosion-proof grabs, and others to suit different working environments. |

Customized

Customized Explosion-Proof Overhead Crane Solutions

Ruicheng offers fully tailored explosion-proof overhead crane systems, designed to meet the exact operational requirements of your specific working environment and load-handling demands. Our customization covers a comprehensive range of technical and functional parameters to ensure optimal safety, efficiency, and compliance.

| Load Capacity | Tailored lifting capacity from light-duty to heavy-load applications, with structural reinforcement as needed. |

| Span | Custom span length adapted to your workshop layout and operational reach requirements. |

| Lifting Height | Adjustable lifting height to accommodate varying facility clearances and vertical handling needs. |

| Working Range | Optimized coverage area and travel limits to suit specific material flow and process layouts. |

| Environmental Conditions | Design adaptations for specific hazards such as extreme temperatures, humidity, corrosive atmospheres, or dusty/explosive environments. |

| Safety Features | Integrated safety systems including overload protection, anti-collision, emergency stop, and explosion-proof enhancements. |

| Automation Level | Customizable control options from manual operation to fully automated, intelligent crane systems with remote monitoring and data logging. |

We collaborate closely with your team to deliver a crane solution that not only meets technical specifications but also enhances operational safety and productivity in demanding environments.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.

Paramater

| Parameter | Unit | ||

| Lifting Capacity | T | 5-500 | |

| Span | M | 10-31.5 | |

| Lifting Height | M | 5-26 | |

| Duty Class | A4-A7 | ||

| Lifting Speed | Trolley Travelling Speed | m/min | 20 – 40 |

| Bridge Travelling Speed | m/min | 30 – 75 | |

| Lifting Speed | Main Hook: | m/min | 1.6 – 12.5 |

| Aux. Hook: | m/min | 6.4 – 20 | |

| Control Mode | Cabin Control+Remote Control/Optional | ||

| Bridge Rail | QU70, QU80, QU100, QU120/Selected based on wheel pressure | ||

| Ambient Temperature | °C | -20 ~ +40 | |