Description

Heavy-Duty & Efficient · Stable & Reliable · Intelligent Integration · Industrial-Grade Heavy Lifting Solution

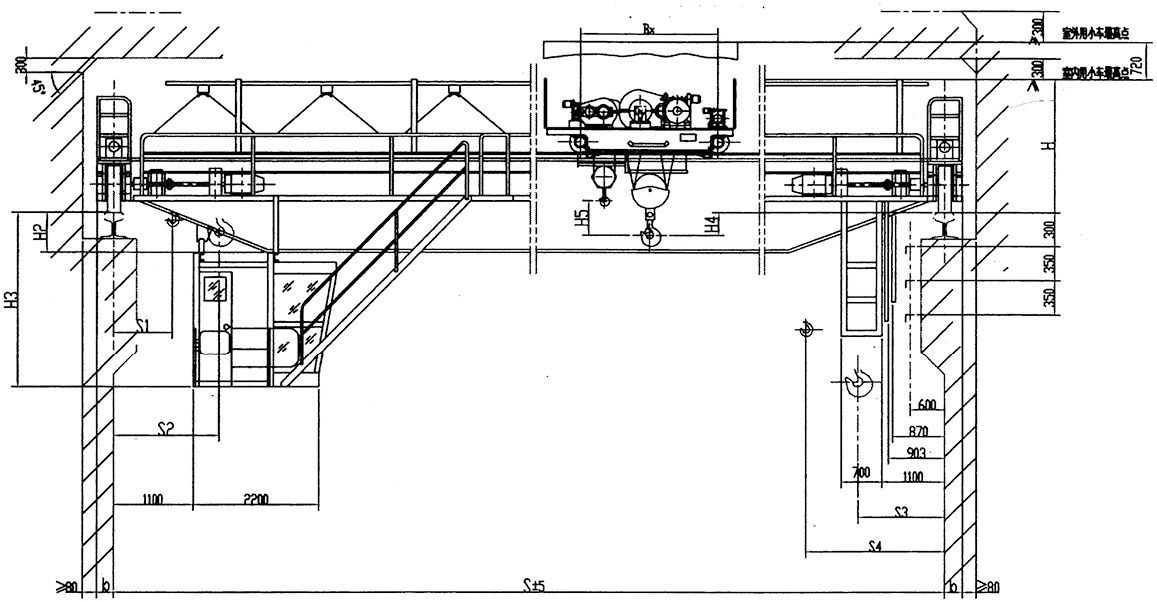

The QD double-girder overhead crane features a heavy-duty box-type double-girder design, offering high load-bearing capacity, strong torsional rigidity, and excellent operational stability. This product is suitable for heavy industry, large-scale manufacturing, logistics hubs, and other applications that require lifting of heavy equipment, handling of large-tonnage materials, and continuous high-intensity operations. Equipped with advanced drive and control systems, it supports high-precision positioning, multi-mechanism coordination, and intelligent scheduling, making it a core piece of equipment for heavy material handling in industrial settings.

Advantages

Box-type double-girder design with excellent bending and torsional resistance, suitable for heavy-load, high-frequency operations.

Three-in-one drive system combined with variable frequency control ensures smooth start/stop and positioning accuracy up to ±5mm.

Integrated load monitoring, anti-collision protection, fault diagnostics, and remote maintenance functions enhance operational safety and management efficiency.

Key mechanisms designed with modularity support quick disassembly and component replacement, reducing downtime.

Critical components made of high-strength alloys and wear-resistant materials, with an overall design life exceeding 30 years.

Application

- Heavy Industry ManufacturingLifting and assembly of large structural components in steel, shipbuilding, and heavy machinery industries.

- Energy & Power IndustryInstallation of power generation equipment, transformer handling, wind turbine component assembly.

- Ports & Logistics HubsContainer loading/unloading, bulk cargo handling, multimodal lifting operations.

- Aerospace SectorAircraft component assembly, engine lifting, maintenance platform hoisting.

- Large Warehousing & Logistics CentersHeavy-duty rack storage/retrieval, heavy material interface operations for production lines. |

Parameter

| Parameter | Unit | ||

| Lifting Capacity | T | 5-500 | |

| Span | M | 10-31.5 | |

| Lifting Height | M | 5-26 | |

| Duty Class | A4-A7 | ||

| Lifting Speed | Trolley Travelling Speed | m/min | 20 – 40 |

| Bridge Travelling Speed | m/min | 30 – 75 | |

| Lifting Speed | Main Hook: | m/min | 1.6 – 12.5 |

| Aux. Hook: | m/min | 6.4 – 20 | |

| Control Mode | Cabin Control+Remote Control/Optional | ||

| Bridge Rail | QU70, QU80, QU100, QU120/Selected based on wheel pressure | ||

| Ambient Temperature | °C | -20 ~ +40 | |

Customization Options

| Rated Lifting Capacity | 5t – 500t, with support for non-standard large-tonnage customization and special load condition verification. |

| Span Range | 10m – 31.5m, customizable for large spans, dual-trolley, or multi-girder systems based on workshop structure. |

| Lifting Height | 6m – 50m, customizable for ultra-high lifting or deep-pit operating environments. |

| Operating Speed | Bridge travel speed: 10 – 40 m/min (VFD adjustable); hoisting speed: 0.5 – 10 m/min. |

| Safety Monitoring Extensions | 3D anti-collision, wind speed monitoring, tilt protection, real-time weighing, video surveillance, and remote diagnostics. |

| Drive Configuration | Dual-drive/quad-drive options; custom motors for explosion-proof, high-temperature, and high-altitude applications. |

| Structural Type | Standard double-girder / off-track double-girder / low headroom type / dual-trolley cooperative system. |

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards.

Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments.

Every unit undergoes rigorous testing prior to shipment, guaranteeing stable performance and safety compliance.

We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle.

Technical Consultation & Solution Design

We provide crane structural selection, track layout planning, intelligent control, and system integration solutions based on your workshop conditions, load characteristics, workflow, and automation needs. Please share your project parameters or schedule an on-site survey—we will customize a high-reliability, high-performance double-girder crane solution for you.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.