Description

Efficient & Intelligent · Precise Handling · Core Equipment for Large Port Operations

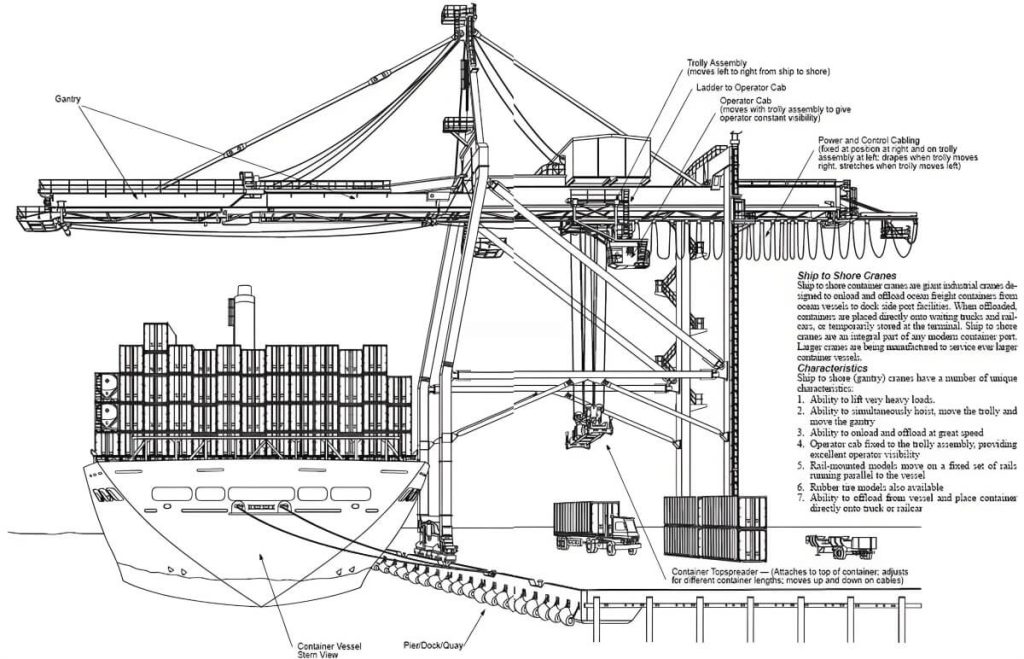

The STS (Ship-to-Shore) Container Crane is the core equipment at port terminals for loading and unloading container vessels. Featuring ultra-long outreach, high lifting height, and heavy-duty operation capability, it directly interfaces with ultra-large container ships for efficient handling operations. With intelligent control systems, modular structural design, and green energy technology, this crane provides reliable, efficient, and environmentally friendly handling solutions for modern container terminals.

Advantages

Outreach up to 50 meters or more, suitable for ultra-large container vessels, improving operational efficiency by over 40%.

Integrated automatic container alignment, precise positioning, and anti-sway systems achieve single-cycle time ≤90 seconds.

Energy feedback systems, lightweight structures, and low-loss drive technology reduce energy consumption by over 25%.

Multiple safety protection systems including hull monitoring, strong wind, intelligent anti-collision, and remote monitoring.

Main structures modularized for quick inspection and component replacement, reducing maintenance costs and downtime.

Application

- Ultra-Large Container TerminalsRapid loading/unloading operations for container vessels over 20,000 TEU.

- Multi-Purpose Terminals Mixed handling operations for containers, bulk cargo, and general cargo.

- Hub Port Transshipment TerminalsInternational route container transshipment and feeder line operations.

- Automated Terminal SystemsFully automated terminals with AGVs, ASCs, and other automated equipment.

- Coastal & Inland River TerminalsEfficient loading/unloading and transfer operations for small to medium-sized container vessels.

Customization Options

| Outreach & Lifting Height | Outreach: 40-80 meters; lifting height: 30-65 meters (above/below rail), supports customization. |

| Spreader System | Single-container spreaders, twin-container spreaders, intelligent recognition spreaders, reefer container spreaders, etc., with quick-change systems. |

| Drive & Control System | AC variable frequency drive, control systems, remote centralized control, intelligent dispatch, and digital twin operation platforms. |

| Structural Configuration | Single-hoist/dual-hoist, dual-trolley/single-trolley, A-frame/H-frame configurations. |

| Safety & Monitoring Systems | Hull scanning systems, anti-collision systems, video surveillance, wind speed monitoring, vibration monitoring, and fault systems. |

| Intelligent Function Expansion | Automatic vessel recognition, intelligent stowage optimization, operational data analysis, predictive maintenance systems. |

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards.

Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments.

Offers one-stop services from planning and design, manufacturing and installation, to operation, maintenance, and upgrades.

We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle.

We provide STS selection design, system integration, and full lifecycle operational support based on your terminal conditions, vessel types, operational efficiency, and automation needs. Please provide terminal parameters or schedule an on-site survey.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.