Description

Efficient Grabbing · Intelligent Control · Multi-Material Compatibility · Industrial Bulk Material Handling Expert

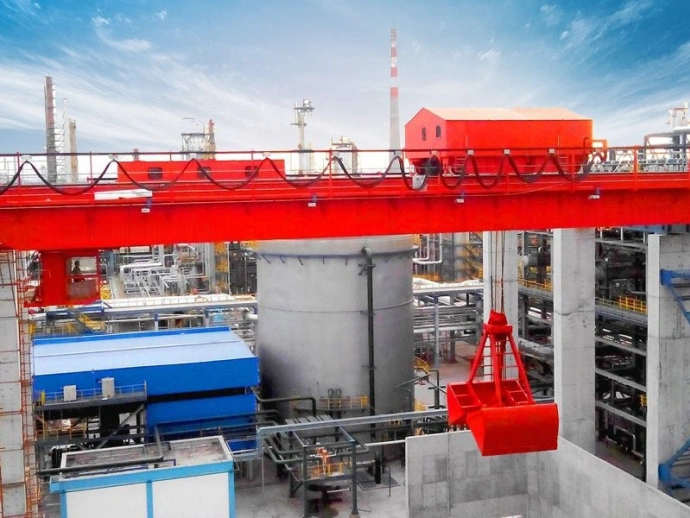

The double-girder grab overhead crane consists mainly of dual main girders, grab buckets, electric trolleys, driver cabins, and electrical control systems. It is equipped with a dual-drum hoisting mechanism arranged symmetrically, offering strong grabbing capacity, stable operation, high efficiency, and heavy load capabilities. The crane is integrated with a fully automated warehouse management system, enabling warehouse location management, task scheduling, equipment monitoring, and data statistics. It interfaces with the user’s production management system to achieve highly intelligent control. Its 3D scanning system for storage areas provides real-time monitoring of material distribution.

Advantages

Equipped with specialized grabs for fast opening/closing and high grabbing ratios, reducing single-cycle operation time by over 30% compared to traditional equipment.

Integrated grab anti-sway, automatic positioning, weighing, and data logging functions, supporting remote monitoring and intelligent scheduling.

Main girder and hoisting mechanism designed for heavy loads, resistant to impact and wear, suitable for high-intensity continuous operations.

Interchangeable grabs including clamshell, multi-tine, and orange-peel designs, adaptable to various material characteristics and operational requirements.

Energy recovery systems and high-efficiency motors reduce energy consumption by over 25%, meeting green industrial standards.

Application

- Port & Terminal Bulk HandlingLoading/unloading and yard transfer of bulk materials such as coal, iron ore, and aggregates.

- Power Industry Fuel HandlingCoal storage and transportation, biomass fuel handling, ash and slag removal in power plants.

- Steel & Metallurgical Raw Material SupplyBlast furnace charging, scrap metal grabbing, sinter ore transfer, raw material yard stacking and reclaiming.

- Grain & Agricultural Product StorageInbound/outbound handling and stacking of bulk materials like grains, feed, and fertilizers.

- Waste Treatment & RecyclingMunicipal solid waste sorting, scrap metal recovery, and solid waste transfer.

Customization Options

| Grab Type & Capacity | Electric hydraulic grabs (1-30 m³) / mechanical grabs / multi-tine grabs / leak-proof grain-specific grabs. |

| Rated Lifting Capacity | 5t – 80t, with support for custom grab force and fill rate. |

| Span & Track Gauge | Span: 10m–31.5m, adaptable to various track layouts and workshop structures. |

| Control System | Manual control / semi-automatic grab-release system / fully automatic stacking-reclaiming programming system / remote centralized control and dispatch. |

| Environmental Adaptation | Dust-proof sealed type / corrosion-resistant type / low-temperature resistant type / explosion-proof type (for combustible dust environments). |

| Intelligent Function Expansion | Real-time weighing system / material identification camera system / grab trajectory optimization / operational data cloud platform management. |

| Structural Type | Single-trolley grab crane / dual-trolley cooperative system / multi-functional stacking-reclaiming crane with cantilever. |

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

Main girders and hoisting mechanisms validated through FEM-based finite element analysis and fatigue testing, ensuring long-term reliability under heavy loads.

Provides end-to-end solutions from standalone automation to intelligent yard scheduling, serving national grain reserves and major ports.

Standardized modules and non-standard grab production in parallel, reducing delivery time by 25% compared to industry averages.

Offers grab maintenance training, fast supply of wear parts, system upgrades, and operational efficiency optimization consulting.

We provide grab selection calculations, track layout optimization, and intelligent control system integration based on your material characteristics, throughput requirements, site layout, and automation level. Please share material samples or schedule an on-site operational video analysis.