Description

Efficient & Intelligent · Precise Dispatching · Large-Yard Automated Handling Expert

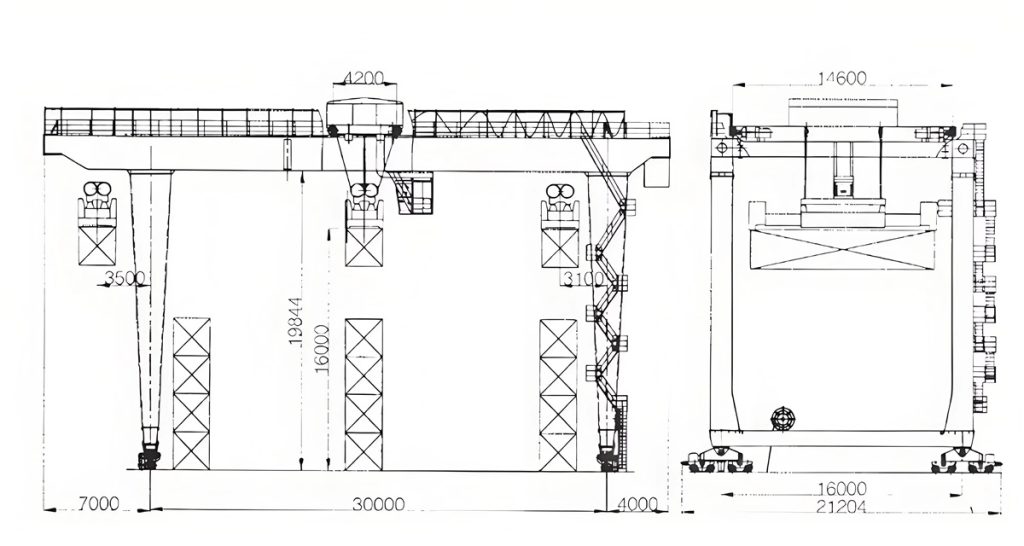

Rail-mounted container gantry cranes are mainly used for unloading, loading and stacking containers in container railway transfer yards and large container storage and transportation yards. Generally, rail-mounted container gantry cranes require a larger clear height in the width direction of the portal legs. Therefore, the upper part of the portal legs is opened in a U shape, and the upper part of the portal legs is connected and a trolley maintenance frame is erected.

The rail-mounted container gantry crane can handle 20′, 40′ and 45′ international standard containers; its lifting capacity is generally 36t and 40.5t.

Depending on the site, container storage and transportation processes, and the types of loading and unloading vehicles, the span can be 26m, 30m, or 35m; generally, they are classified into three types: upper trolley rotation, lower spreader rotation, and non-rotation.

Advantages

Enables multi-layer stacking in limited space, improving yard space utilization by over 50% compared to traditional equipment.

Supports automatic container alignment, precise positioning, intelligent dispatching, and unmanned operation, significantly reducing manual intervention.

Positioning accuracy ±10mm, spreader anti-sway system ensures smooth operation, suitable for rapid loading/unloading.

Equipped with energy feedback systems, variable frequency drives, and lightweight design, reducing energy consumption by over 30% compared to traditional.

Features intelligent safety systems including 3D anti-collision, container monitoring, strong wind, and remote monitoring.

Application

- Container Terminal Yards Automated container storage, loading/unloading, repositioning, and inspection operations.

- Railway Container Central Stations Container train loading/unloading, yard transfer, multimodal transport.

- Inland Dry Ports & Logistics ParksContainer distribution, storage, transfer, and cross-border e-commerce logistics operations.

- Multimodal Transport Hub Stations Transshipment and handling operations for sea-rail and road-rail container transport.

- Special Container Handling Areas Dedicated stacking and power management for refrigerated containers, hazardous material containers, and tank containers.

Customization Options

| Span & Stacking Height | Span options: 6+1 to 8+1 lanes; stacking height: 1-over-4 to 1-over-6, with support for higher stacking customization. |

| Spreader System Type | 20/40ft automatic telescopic spreaders, twin 20ft spreaders, reefer container spreaders, intelligent recognition spreaders, etc. |

| Drive & Control System | AC variable frequency drive, fully automated control system, remote centralized monitoring, digital twin dispatching platform. |

| Rail & Travel Mode | Single/double rail configuration, all-wheel drive and steering, multi-crane cooperative dispatching system. |

| Safety & Monitoring Functions | Laser anti-collision, container recognition, wind speed monitoring, video tracking, fault diagnostics, and predictive maintenance systems. |

| Environmental Adaptability | Windproof anchoring systems, anti-corrosion treatment, low-temperature adaptability design, lightning protection, and emergency power. |

| Intelligent Extensions | Automatic slot management, truck guiding system, intelligent lighting, energy efficiency analysis, and carbon emission monitoring systems. |

Why Choose Us?

We possess over 15 years of dedicated experience in the lifting equipment industry, supported by mature and reliable technology.

All our products are certified with CE and ISO, ensuring full compliance with international quality and safety standards.

Our designs are fully customizable to adapt to a variety of working conditions, spatial constraints, and operational environments.

Provides end-to-end services from RMG selection and yard layout optimization to intelligent dispatch system integration.

We offer professional technical guidance and comprehensive after-sales service, providing continuous value throughout the product lifecycle.

We provide RMG selection and configuration, yard traffic flow optimization, and intelligent management system solutions based on your yard scale, operational workflow, container types, and automation goals. Please share your yard layout plan or schedule an on-site survey —we will create an efficient, green, and intelligent container yard solution for you.

We don’t just provide products—we deliver safe, efficient, and sustainable lifting solutions built to last.